MODUŁOWA FORMIERKA PIONOWA

FCV 4matic

Modułowa formierka pionowa kartonów klapowych FCV 4matic formuje i zakleja równocześnie cztery różne kartony. Formierka FCV 4matic oferowana jest w wykonaniu dwuformatowym lub czteroformatowym.

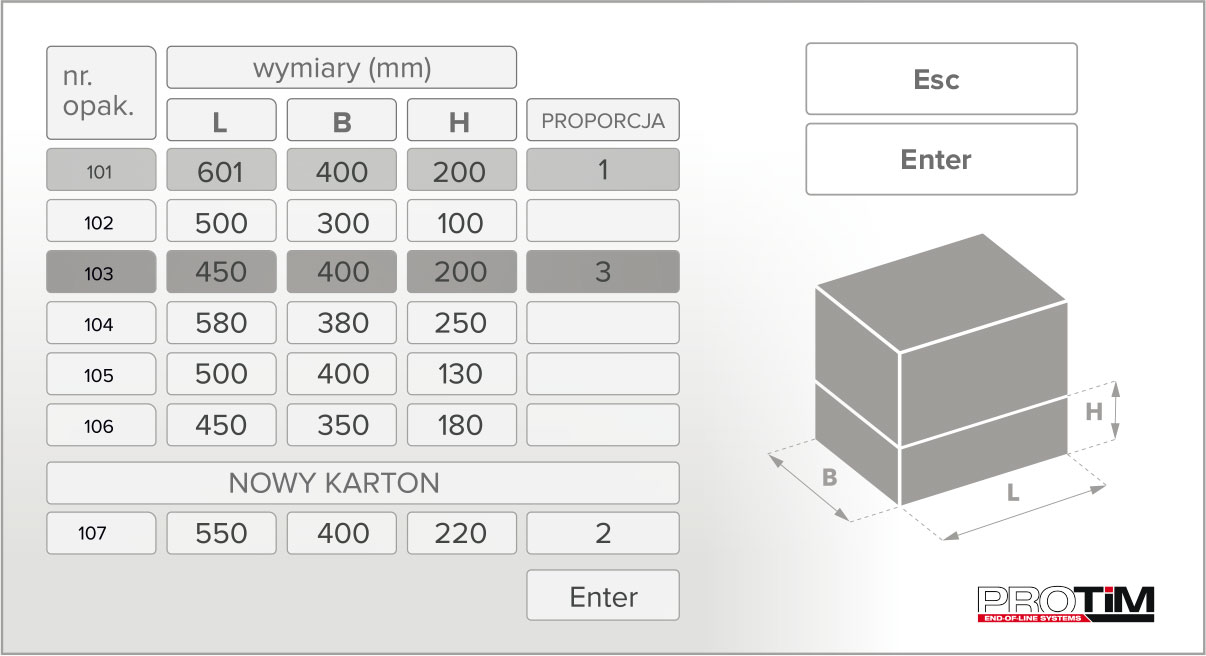

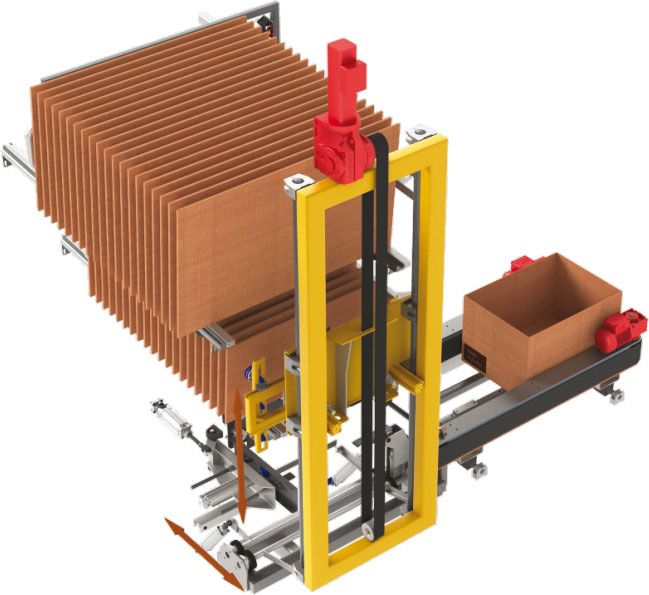

FORMIERKA DWUFORMATOWA może być wykonana jako dedykowana dla dwóch konkretnych wymiarów kartonów lub wieloformatowa, gdzie wymiary kartonów są dowolne w obsługiwanym zakresie. Przezbrojenia formierki dedykowanej realizowane są pneumatycznie, natomiast w formierce wieloformatowej przezbrojenia odbywają się za pomocą serwonapędów.

Integralnym zespołem formierki dwuformatowej jest stacjonarny manipulator pobierający przemiennie kartony z magazynów kartonów, przemieszczający je pionowo w rejon formowania.

FORMIERKA CZTEROFORMATOWA jest maszyną uniwersalną. W każdym z czterech magazynów mogą znajdować się zamiennie kartony o różnych wymiarach objętych zakresem wymiarowym maszyny.

W odróżnieniu od formierki dwuformatowej, czteroformatowa wyposażona jest w przejezdny manipulator pobierający selektywnie kartony z poszczególnych magazynów kartonów i dostarczający je do zespołu formowania. W formierce czteroformatowej wszystkie przezbrojenia oraz ruchy manipulatora realizowane są na bazie serwonapędów i aktuatorów oraz napędów liniowych

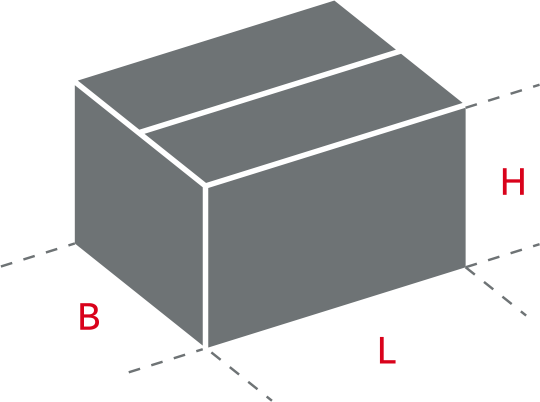

PODSTAWOWY ZAKRES OBSŁUGIWANYCH WYMIARÓW KARTONÓW:

- B min = 200

- B max = 300

- L min = 300

- L max = 600

- H min = 100

- H max = 400

Wynika z obowiązujących normatywów oraz optymalizacji ułożenia kartonów zbiorczych na

paletach EUR i USA.

Możliwe jest indywidualne wykonanie w innym zakresie wymiarowym.

Formierka oferowana jest w dwóch opcjach różniących się sposobem zaklejania klap kartonów:

- Taśmą (T)

- Poprzez klejenie na gorąco (HM)

Rozwiązanie techniczne formierki umożliwia jej samodzielną pracę, lub w różnych konfiguracjach modułowego systemu pakowania produktów w kartony zbiorcze.

Możliwe aplikacje:

- Różne możliwości zastosowania obu metod klejenia

- Inne wymiary formowanych kartonów – formierki dedykowane

- Maszyna może być wykonana jako lewa lub prawa zależnie od potrzeb klienta

Wyróżnienie :

Modułowa formierka FCV 4matic jest urządzeniem całkowicie innowacyjnym, w związku z tym PROTiM rozpoczął proces ubiegania się o przyznanie patentu na wynalazek.

ZALETY FCV 4matic

- Formuje i zakleja cztery różne kartony równocześnie

- Kompaktowość i zwartość konstrukcji.

- Wysoka jakość i niezawodność działania uzyskana przez zastosowanie zdublowanych systemów formowania i decentralizacji obwodów podciśnienia

- Mała powierzchnia zabudowy.

- Możliwość zwartych systemów odbioru produktów z maszyny

- Możliwość zastosowania dedykowanych rozwiązań pod potrzeby klienta

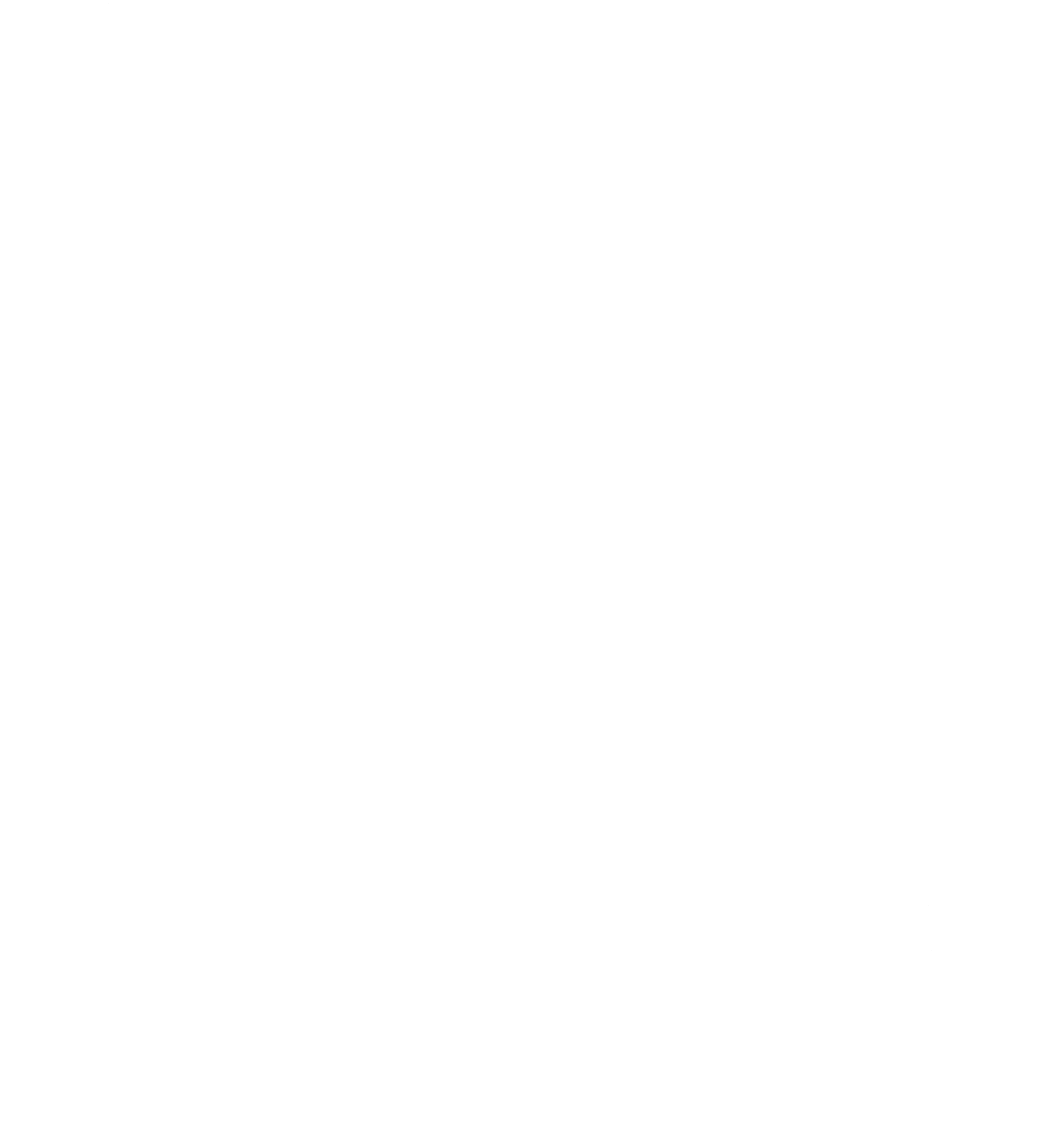

- Wizualizacja procesu na panelu zapewniająca wysoką czytelność, łatwość obsługi (tryb serwisowy, sygnalizacja i lokalizacja stanów awaryjnych), możliwość raportowania, komunikacji – pracy pod systemem nadrzędnym.

Widok

360o

FCV 4matic

PARAMETRY TECHNICZNE:

- masa 960 / 1150 kg

- wydajność 6 - 10 szt./min

- zasilanie 3 x 400 V

- moc zainstalowana 1,1 kW

- pneumatyka:

- ciśnienie robocze 5,5 – 6 bar

- zapotrzebowanie powietrza 0,05 m3/cykl

Formierka FCV 4matic wykonana jest w najwyższych standardach technicznych, gdzie wykorzystane są komponenty takich firm jak SEW, FESTO, SICK, LENZE, OMRON, BOSCH-REXROTH, HIVIN

Sterowanie zależne od standardów klienta realizowane jest na sterownikach firm SIEMENS, ALLEN BRADLEY, BECKHOFH lub OMRON. Szafa sterownicza może być wyposażona w router do zdalnej komunikacji ze sterownikiem poprzez sieć (np. GSM) do świadczenia teleserwisu.