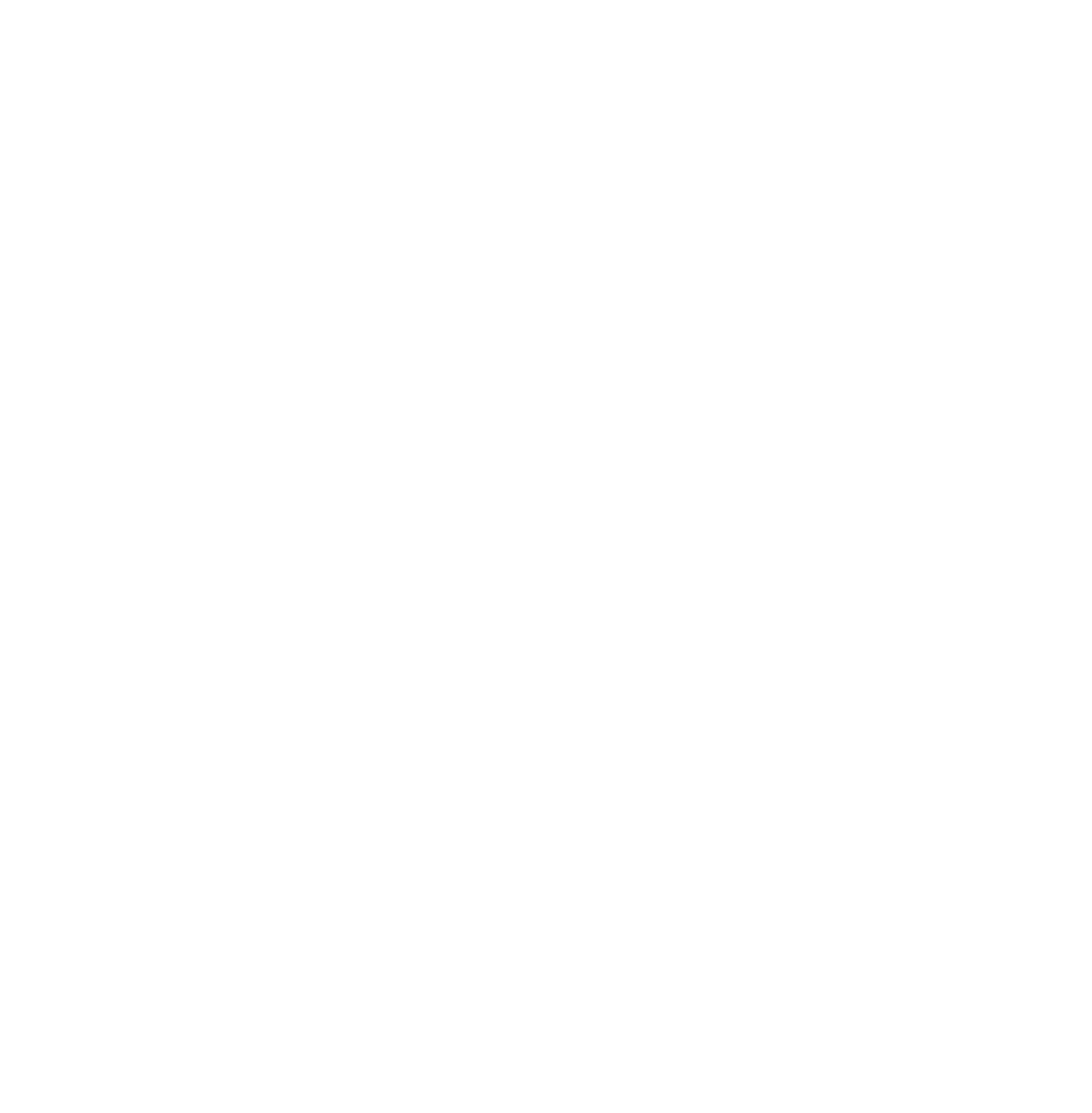

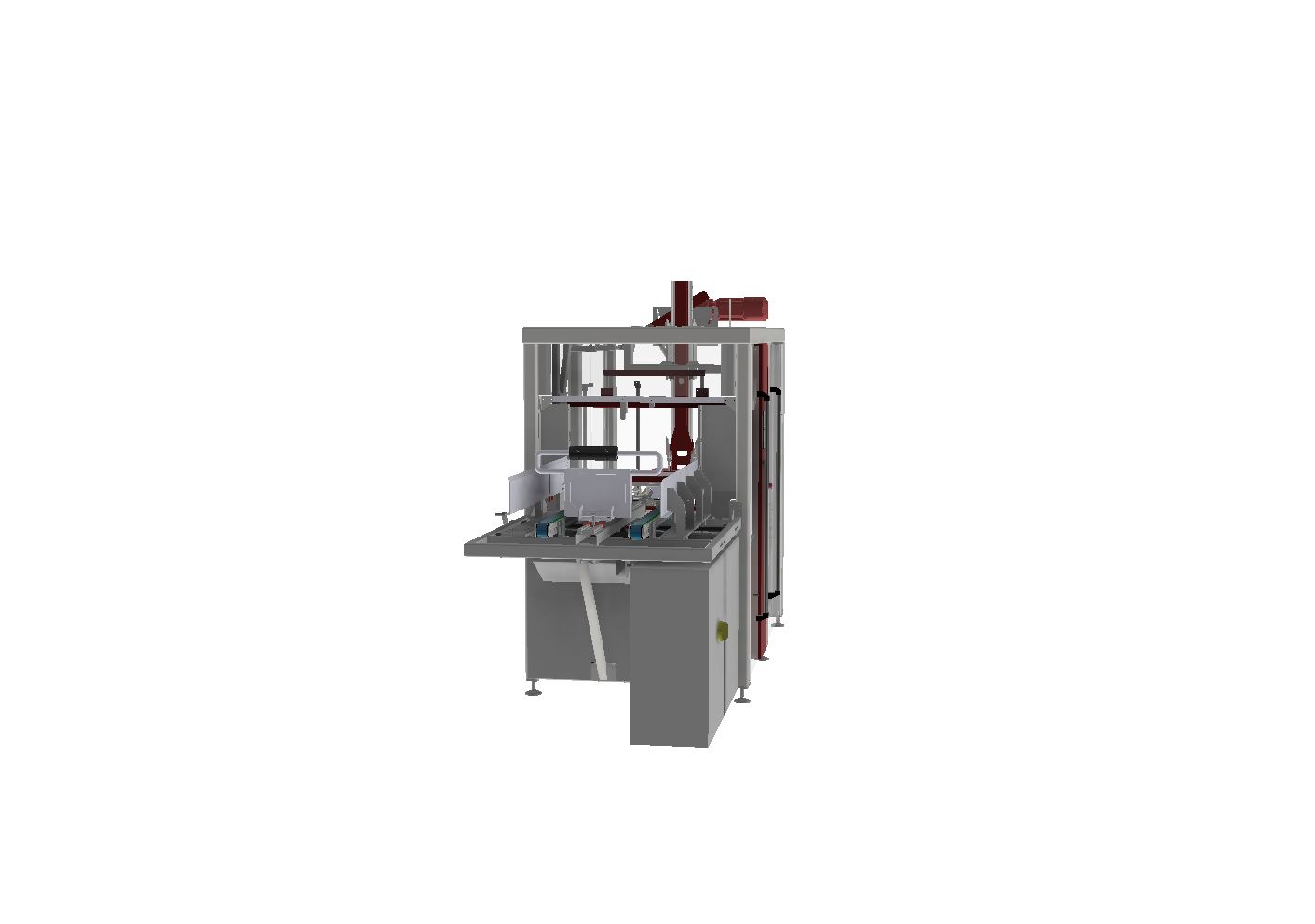

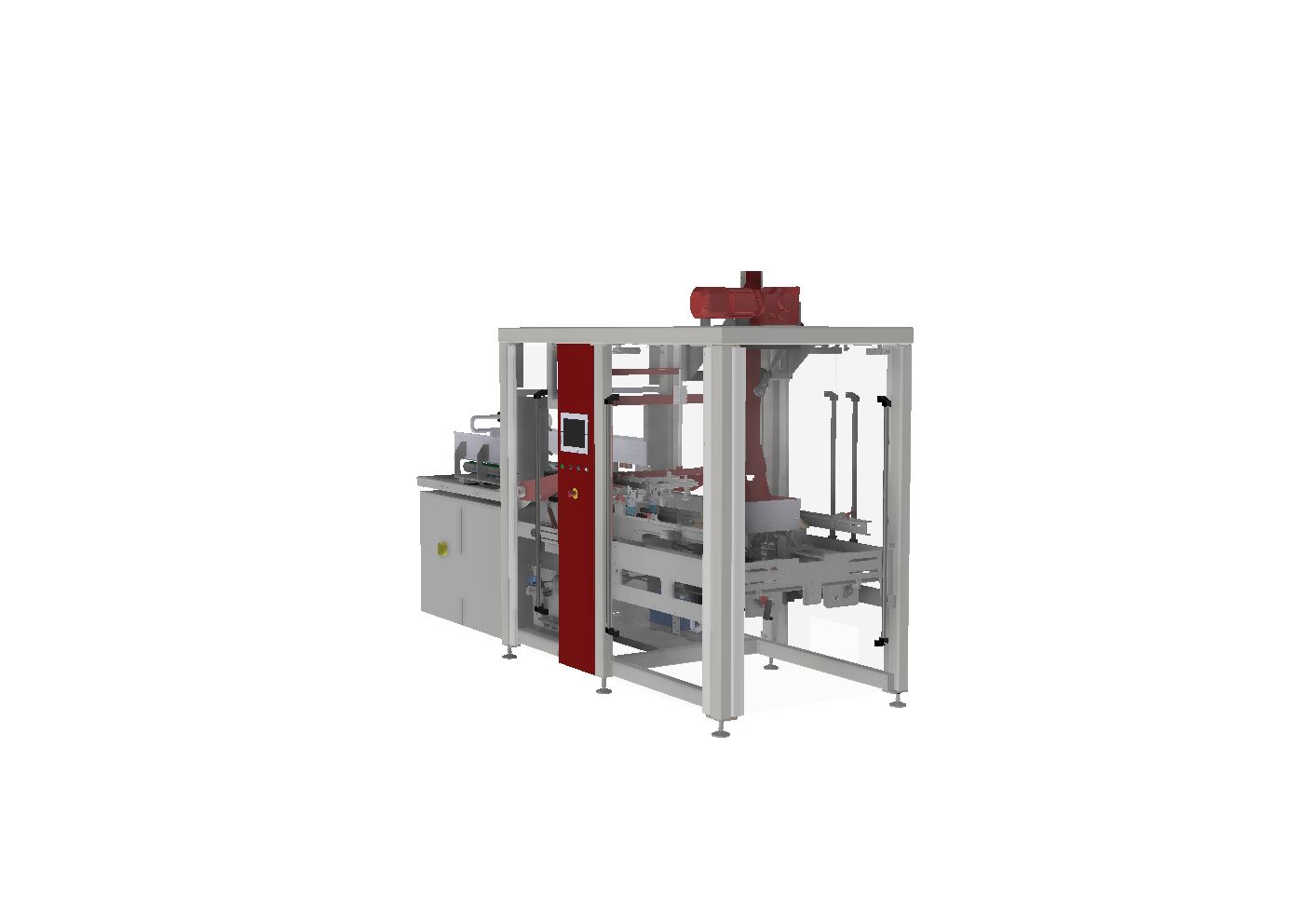

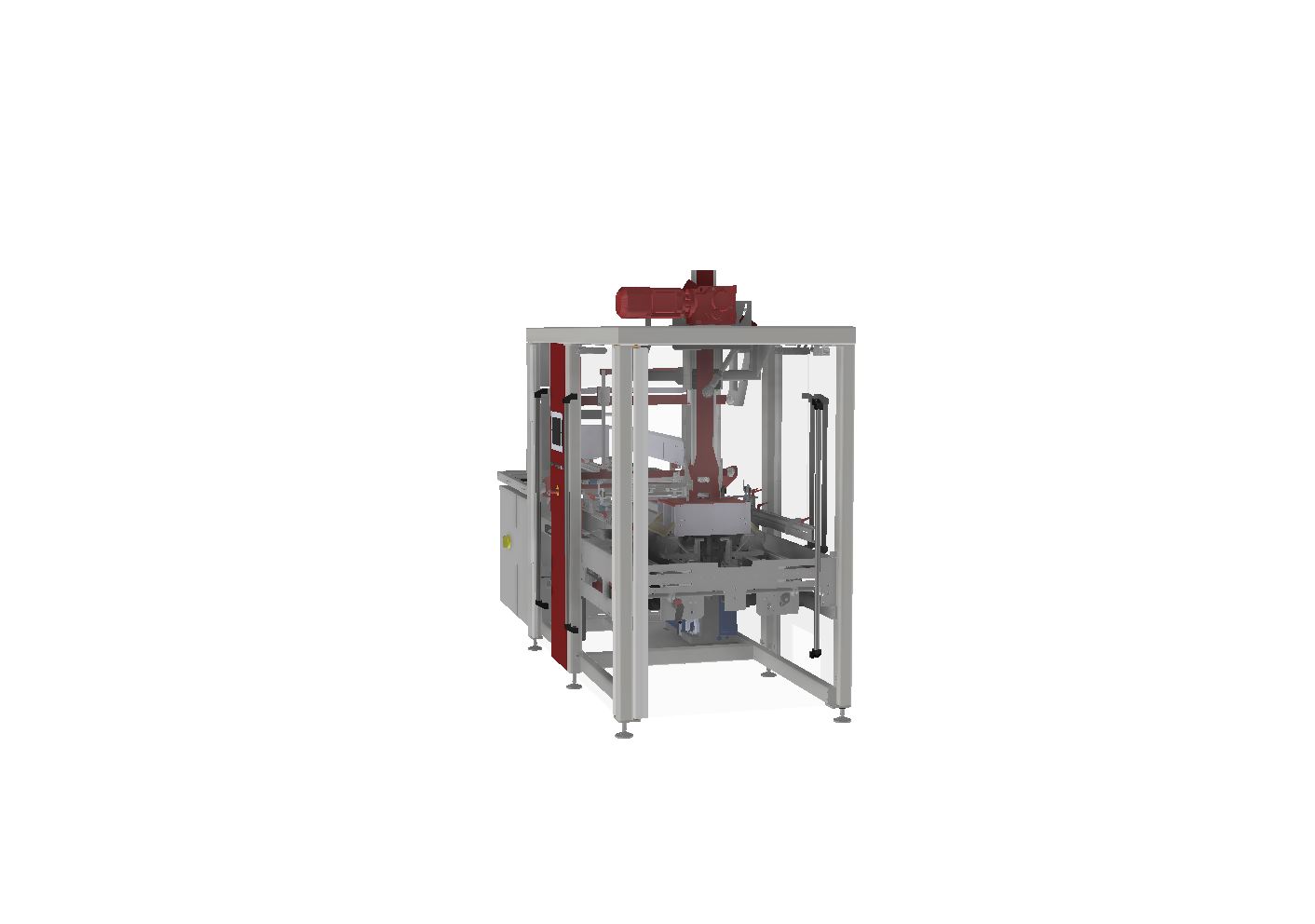

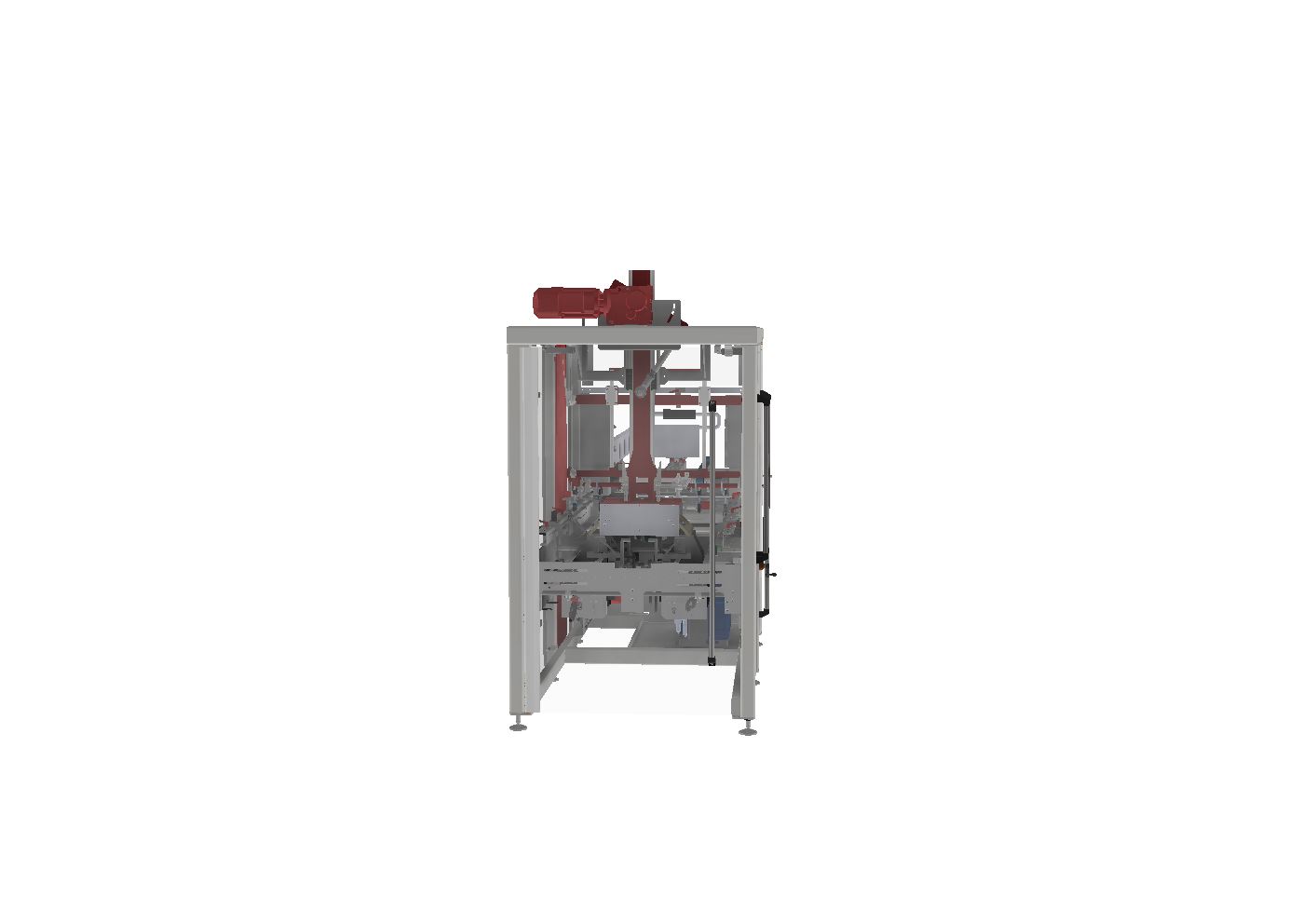

Horizontal tray former

FTHT 6

Horizontal tray former is dedicated for erecting different shape and dimensions trays using hot melt.

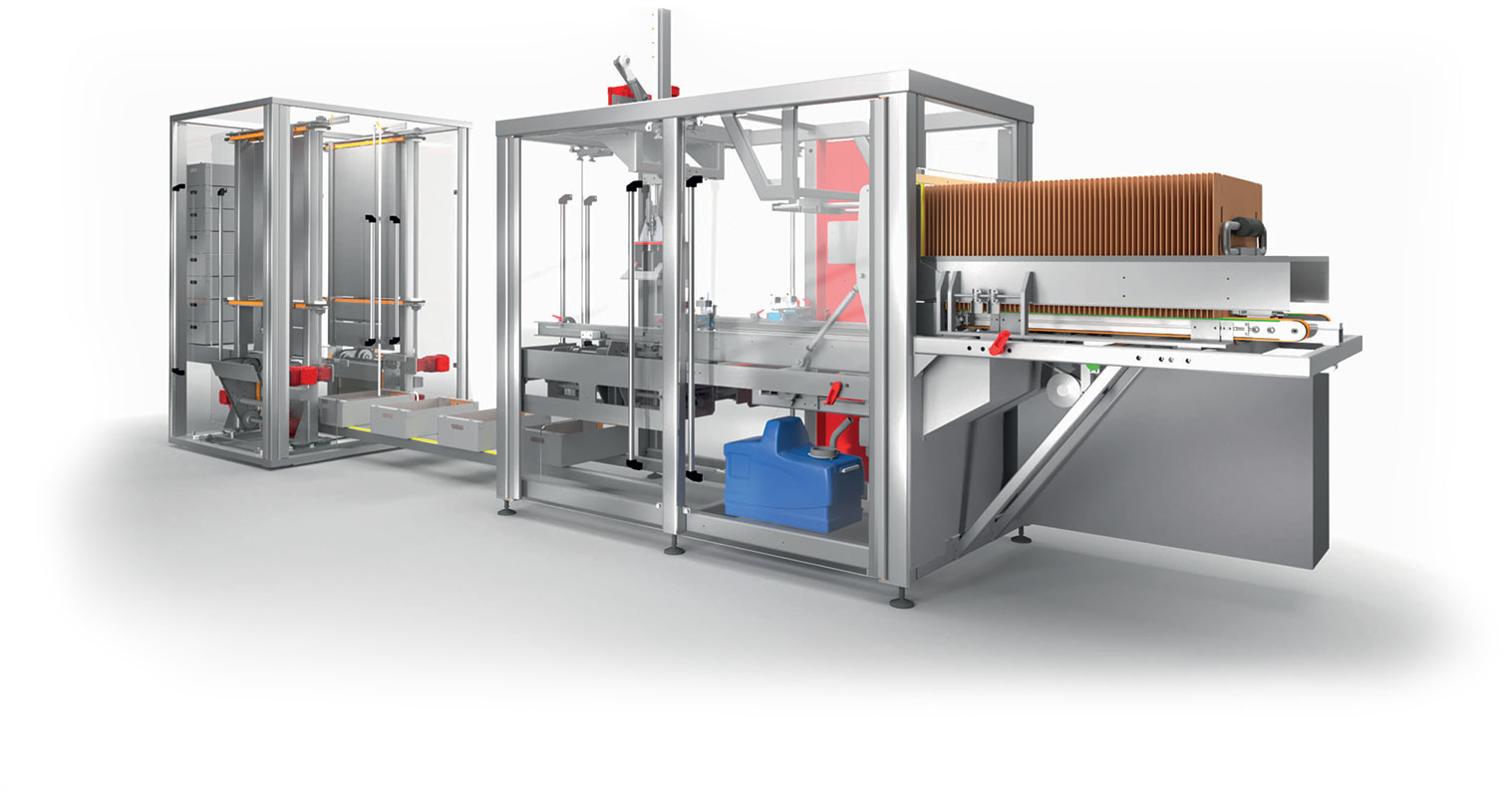

Basic range of boxes dimensions:

- L min = 400

- L max = 900

- H min = 50

- H min = 250

- B min = 300

- B min = 900

- lp min = 30

- lp max = 50

- bp min = 30

- bp max = 50

It results from existing standards and possible matrixes of composition of trays on EUR and ISO pallets.

Standard equipment:

- PLC controller and multifunctional HMI touch panel 7,5”.

- Nordson glue system.

- Non driven blanks magazine with capacity about 150 pcs.

Optional equipment:

- Bigger driven blanks magazine with capacity about 500 pcs.

- Multifunctional HMI touch panel 12”

- GSM teleservice module

- Automatic glue feeding system with special bin. Much more bigger capacity than standard.

- Glue path modulators to ensure savings on glue.

- Managing Nordson system with master HMI touch panel and main controller.

Advantages FTHT 6

- Compactness of the structure.

- Modular construction which allows extension with additional modules.

- Short time of adjustment to other size/format.

- Universal solution allows to work as independent unit or as a part of goods flow system.

- Visualization of process which ensures easy operation (service mode), signalization and identification of breakdowns reasons.

Technical solution of tray former allows to work it as independent unit or as a unit cooperating with stacking device. Also cooperation with other devices connected with goods flow systems is possible.

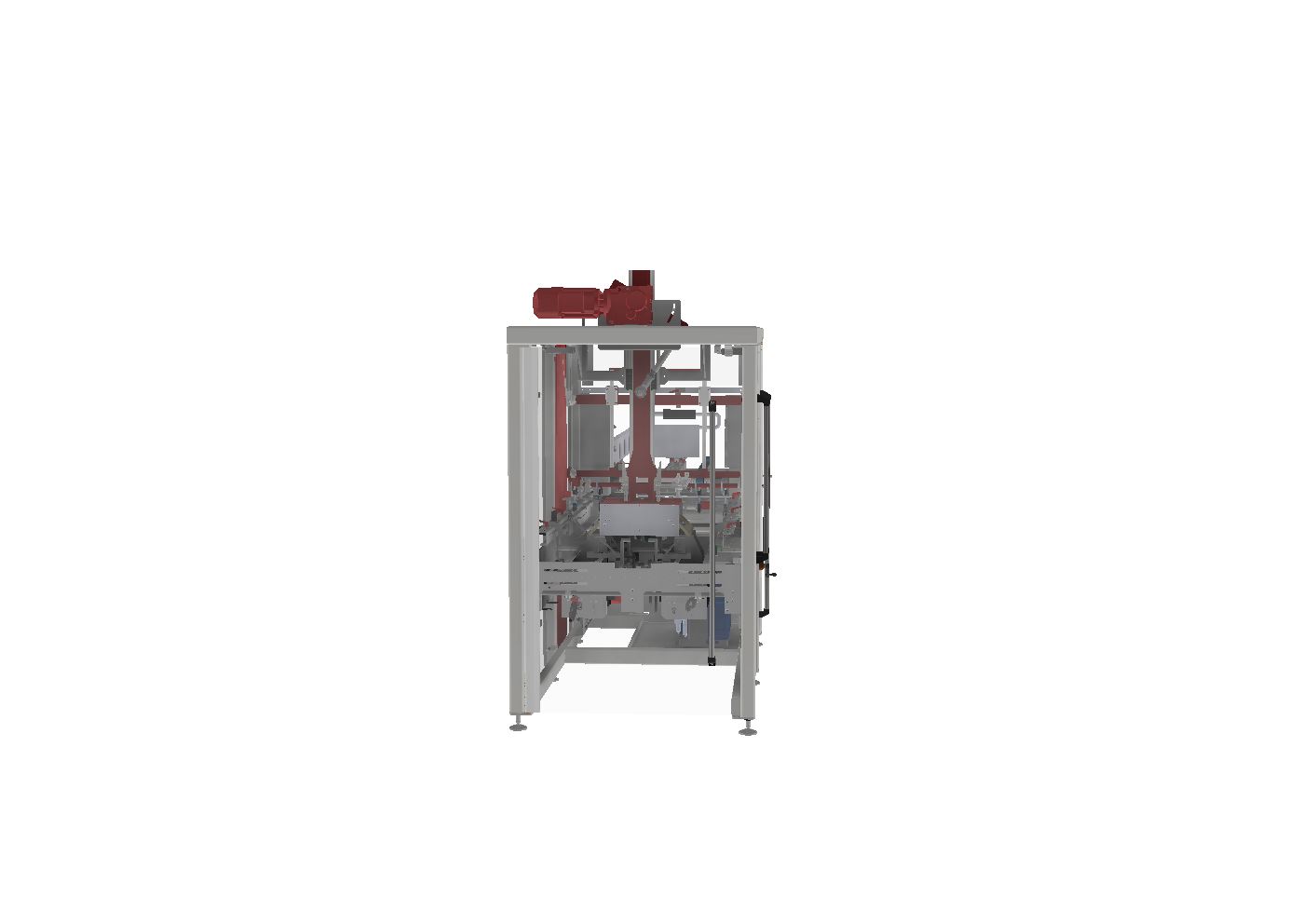

View

360o

FTHT 6

TECHNICAL PARAMETERS:

- weight 1650 kg

- efficiency – up to 25 trays/minute

- power supply 3 x 400 V

- installed power 9 kw (including glue system)

- pneumatics:

- required air pressure 5,5 – 6 bar

- air consumption 0,35 - 0,7 m3 (including hotmelt unit with 25 cycles)

TECHNICAL STANDARDS:

- pneumatics FESTO

- drives SEW

- servodrives OMRON

- sensors SICK

- control system OMRON

- glue system NORDSON